What is the Auto Cut feature on the laminating machine?

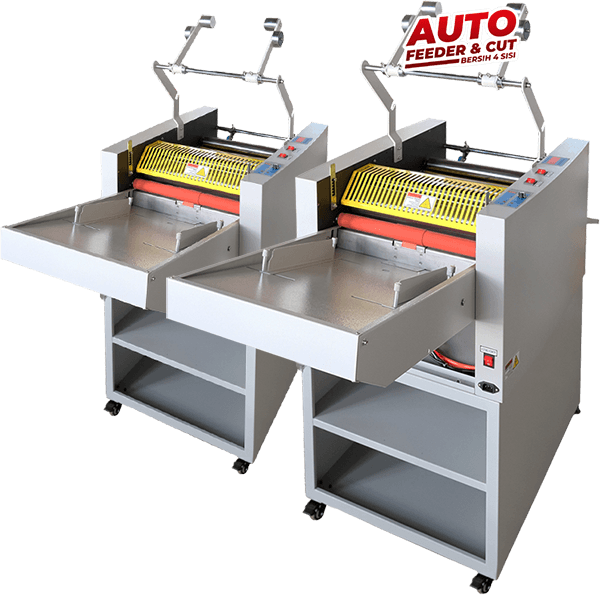

Telson 390 W3320 laminate machine

The auto cut feature is an automatic cutting system found in several types of modern laminating machines. Where the results of the lamination will be cut automatically according to the predetermined length. That way, the operator no longer needs to cut the results manually using a cutter or scissors after the laminated process is complete.

Auto cut laminating machine It is suitable for use in large scale laminated processes or mass production, such as in the printing industry, government agencies, and commercial printing. Its efficiency is proven to be able to accelerate the workflow while maintaining the results of lamination.

The main component in the auto cut system

To understand how the Auto Cut feature works, we need to get to know some of the main components that play a role in this process. Some of them are:

- Long sensor or infrared sensor

This sensor serves to detect the length of the document being laminated. When a certain length is reached, the sensor will send a signal to start the cutting process. - Automatic cutter roller

Is the main part of the auto cut system whose duty is to cut the laminate results. Cutting is done horizontally with the help of the rear and middle roller which will move according to the desired length of the piece. - Motor and Mover Solenoid

Used to move the cutter roller. Usually transferred electrically or using air pressure (pneumatic). - Digital Check Panel

This is where the operator can adjust the length of the cut, lamination speed, to work mode (manual or auto cut). - Cutting and Porforation Knives

Functions to cut the side of the laminated result vertically. Both of these knives are mounted on the material stand and can be arranged manually according to the width of the laminated media.

How the auto cut laminating machine works

In general, the work process of the Auto Cut feature can be explained in several stages:

1. Initial settings

The operator inserts paper or document into the machine and adjusts the length of the cut through the digital panel. For example, if the cut length is arranged 50 cm, then every 50 cm of the laminated document will be automatically cut.

2. Laminated process

Paper enters the machine and passes through a hot roller (hot roller) which will melt glue in the laminated plastic layer. After that, the results of the lamination will come out through the front of the engine.

3. Detection of the length by the sensor

When the results of the laminate come out and reach the length that has been set, the sensor will detect the position. Then the system will give orders to the cutting unit.

4. Automatic cutting

The cutting unit works according to instructions and cuts laminated results quickly and precisely. This process takes place in a very short time, so it does not interfere with the next laminate flow.

5. Repeated process

The process will continue to be repeated for each document sheet or paper that enters the machine.

Technology auto cut laminating machine This is designed to be able to work sync with the laminated process. That is, there is no significant pause or delay when the cutting process occurs.

The advantages of using laminating machines with auto cut

Using a laminating machine that has Auto Cut features provides various advantages, including:

1. Save time and energy

With an automatic cutting system, operators no longer need to cut laminate results one by one. This saves time, especially when processing hundreds of sheets in one session.

2. The results of the precision cut

The sensor and cutting system works accurately so that the cut results become neater and more consistent. This is difficult to achieve if cutting is done manually.

3. Increase productivity

Because the process of lamination and cutting runs continuously without stopping, productivity also increases significantly.

4. Reducing operator error

Errors due to sloping or inappropriate cuts can be reduced by this automatic system.

5. Appear more professional

The results of neat and precise laminated reflect professional work quality, very suitable for companies, educational institutions, and printing services.

Types of laminating machines that have auto cut features

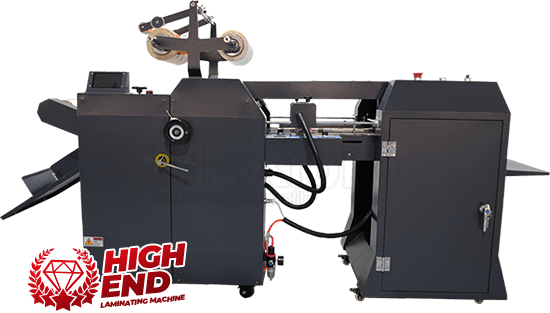

Telson laminate machine 520 w5421

At present, many roll laminated machines such as Telson 390 W3320 laminate machine which has been equipped with the Auto Cut feature. Usually used for large sizes such as A3, A2, even F4.

Some laminated machines such as type 390 W5421 And 520 W5421 From Maxipro has even been equipped with additional features such as counters, auto stops, to the auto feeder input system which is equipped with a paper tray that can accommodate thousands of paper at once.

In the Indonesian market, laminating machines with this feature are becoming popular among the graphics and digital printing industries. The price is indeed higher than the usual engine, but comparable to the benefits and efficiency provided.

Tips for using the Auto Cut feature optimally

So that the Auto Cut feature works optimally and does not cause problems during the lamination process, here are some practical tips that you can apply:

- Sensor calibration regularly

Make sure the long sensor works according to the initial settings. Sensors that are not calibrated can make the pieces miss. - Clean the knife regularly

The rest of the glue or plastic laminated attached to the knife can reduce sharpness. Clean regularly so that the cut results remain maximum. - Use the speed according to the engine capacity

Do not impose high speed if the engine does not support. This can interfere with the automatic cutting process. - Do a trial before mass production

Always do the first cut test to make sure all settings are appropriate.

Conclusion

In this increasingly speeding world, who still has time to cut the results of laminate one by one? Feature Auto cut in laminating machine is an answer for those of you who want to work faster, neater results, and certainly more professional. Starting from automatic detection, precision pieces, to work efficiency – all designed to make work much lighter.

And when talking about Auto Cut laminating machines, Maxipro have a champion. Telson 390 W3320, 390 W5421 laminate engine, up to 520 W5421 – all of which are equipped with sophisticated auto cut features, even equipped ward off, Stop automaticallyuntil Automatic feeder tray which fit thousands of sheets of paper. Very suitable for printing that requires speed, quality, and high efficiency.

So, if your business wants to level up from the manual cutting system that makes aches and waste time, now is the time to switch to Auto cut laminating machine from maxipro. Not just a machine, this can also be an investment for the future of your business.

Check the Auto Cut laminate machine in Maxipro and get a free consultation now!

Game Center

Game News

Review Film

Rumus Matematika

Anime Batch

Berita Terkini

Berita Terkini

Berita Terkini

Berita Terkini

review anime